وکیوم فرمینگ؛ خدمات تخصصی تولید بستهبندی و قطعات وکیوم

صنایع وکیوم فرمینگ آرارات، مرجع تخصصی طراحی و تولید انواع بستهبندیها و قطعات کاربردی وکیوم فرمینگ.

ما همراه مطمئن برندها هستیم؛ با ارائه خدمات کامل از قالبسازی تا بستهبندی دقیق، کیفیت و نوآوری را تضمین میکنیم.

خدمات ما

تولید انواع بستهبندی وکیوم فرمینگ بلیستر پرسی، کشویی، استند، تاشو، هایفرکانس و اسکین

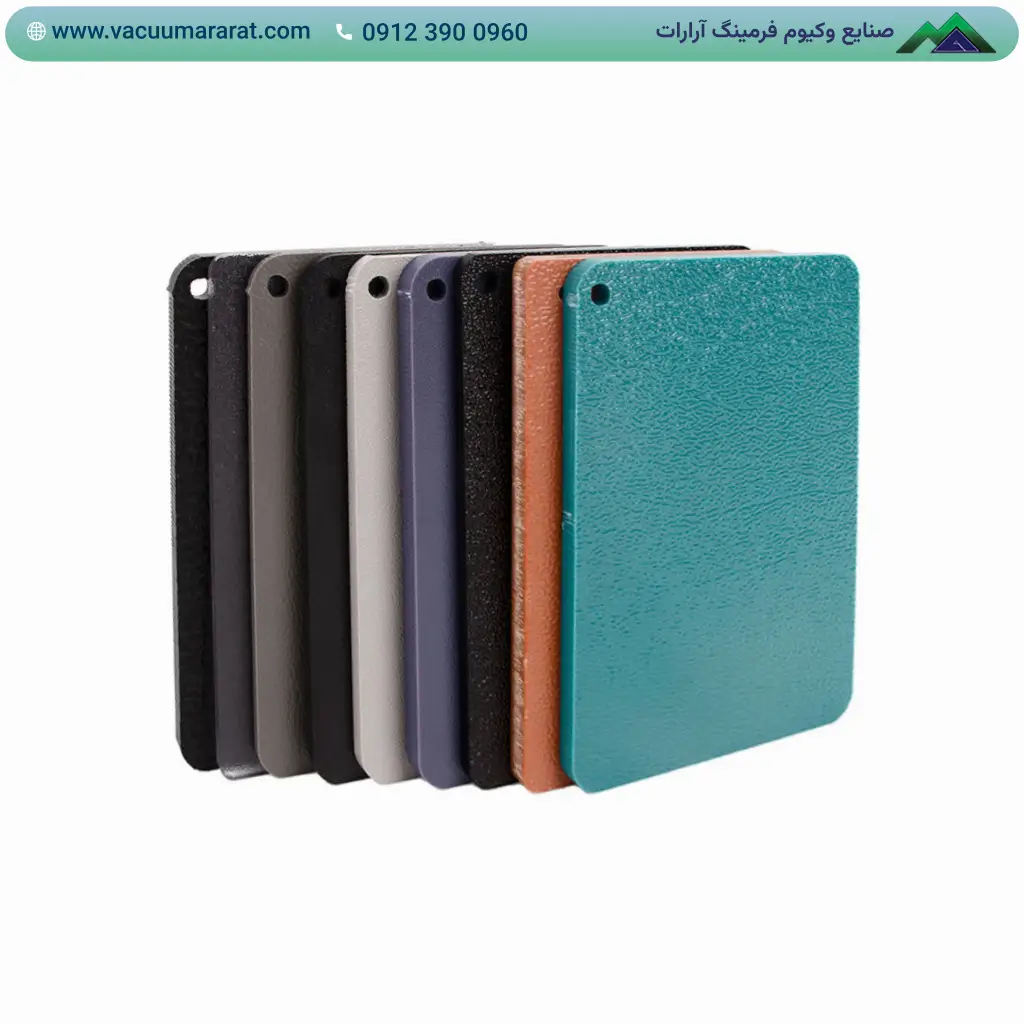

تولید انواع قطعات نازک و ضخیم وکیوم فرمینگ ABS , HP , PET , PVC برای استفادههای مختلف

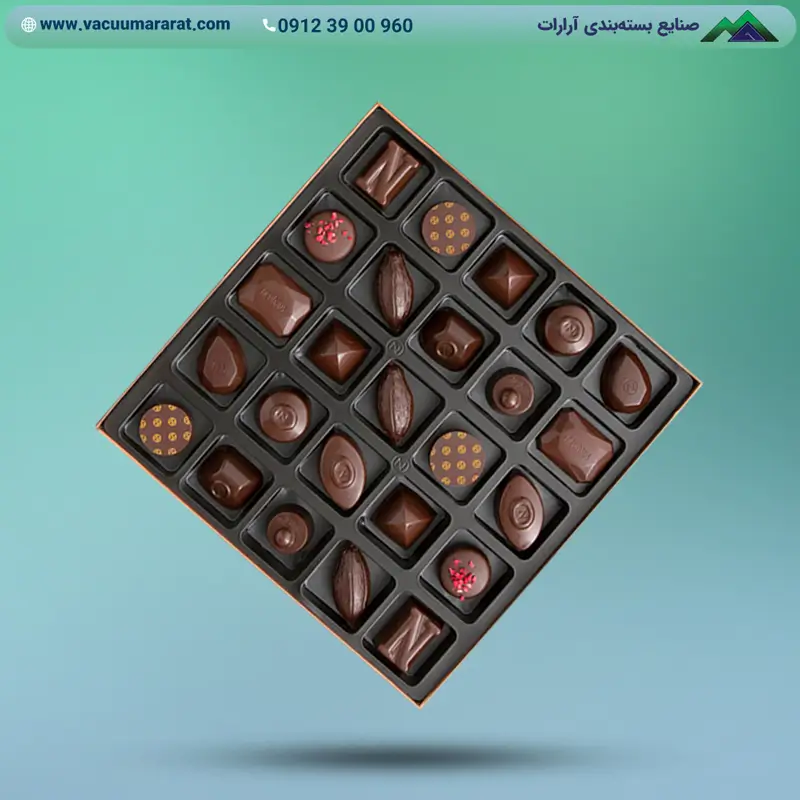

تولید بسته بندی شکلات با جعبههای وکیومی، طلقی، مقوایی و ترکیبی

طراحی و ساخت قالب وکیوم فرمینگ CNC

نمونهکارهای ما

وکیوم فرمینگ آرارات

وکیوم فرمینگ و صنایع بسته بندی آرارات با مدیریت مهندس لِویک شیروانیان به لطف یزدان سپنتا بیش از ۲۵ سال در زمینه تولید قطعات وکیوم فرمینگ، بسته بندی وکیوم فرمینگ و جعبه طلقی (دایکات) دارای سابقه و تجربه پیروزمندانه است.

این مجموعه یکی از شرکتهای برتر و شناخته شده در صنعت وکیوم فرمینگ است و با اندوختهای گرانبها از دانش فنی و تجربه یکی از شرکتهای پیشرو در این حوزه میباشد و افتخار همکاری با برندهای مطرح همچون لبنیات روزانه، لبنیات بل، بلور کاوه و محصولات آرایشی مای را در کارنامه خود دارد.

ما با بهره گیری از تکنولوژیهای نوین، تضمین کیفیت محصولات و خدمات خود را به مشتریان ارائه میکنیم. همچنین با بکارگیری تجهیزات پیشرفته، به صورت حرفهای و با دقت بالا، محصولات مورد نظر مشتری را بسته بندی و ارائه میکنیم.

طی سالهای پیروزمندانه گذشته تا امروز، آرارات با سابقه و تجربه خود در این حوزه، همواره در تلاش است تا با ارائه خدماتی با کیفیت بالا و قیمت مناسب، اعتماد و رضایت مشتریان خود را به دست آورد و رویای رسیدن به رتبهی برتر در صنعت بسته بندی را به واقعیت تبدیل کند.

ما در این مسیر استوار و پابرجا خواهیم ماند.

چرا آرارات؟

بیش از دو دهه تجربه علمی و فنی

ما بیش از ۲۵ سال در صنعت وکیوم فرمنیگ و بسته بندی وکیوم فرمینگ سابقه داریم و یکی از شرکتهای برتر در این حوزه هستیم.

خط تولید دقیق و پیشرفته

دستگاهها و ماشینآلات خط تولید ما از آخرین تکنولوژی روز دنیا پیروی میکنند.

تضمین کیفیت

ما با بهرهگیری از تکنولوژیهای نوین و متخصصین ماهر، کیفیت محصولات و خدمات خود را تضمین میکنیم

مشاوره، طراحی و اجرای منحصر به فرد

آرارات از ۰ تا ۱۰۰ کار کنار شماست تا به بهترین نتیجه و محصول نهایی دست یابید

استفاده از مواد اولیه مرغوب

ما از مواد اولیه با کیفیت در تولیدات خود استفاده میکنیم تا کیفیت محصول نهایی مطلوب باشد.

توان تولید در تعداد بالا

خط تولید ما دارای ظرفیت بالایی است و توانایی پاسخگویی به مشتریان بزرگ را داراست.

تلاش برای رضایت مشتری

ما از مواد اولیه ما با ارائه خدمات با کیفیت و قیمت مناسب، همواره در تلاشیم تا اعتماد و رضایت مشتریان را به دست آوریم. با کیفیت در تولیدات خود استفاده میکنیم تا کیفیت محصول نهایی مطلوب باشد.

زمانبندی دقیق

ما با ارائه خدمات با زمانبندی تحویل دقیق، نیازهای مشتریان را در تمامی مراحل کار برآورده میکنیم.

بهره گیری از فن آوری روز دنیا

ما همواره تلاش کردهایم تا با تحقیق در زمینه کاریمان آگاهی و دانش خود را به روز نگهداریم.

آرارات انتخاب برترینها

وکیوم فرمینگ

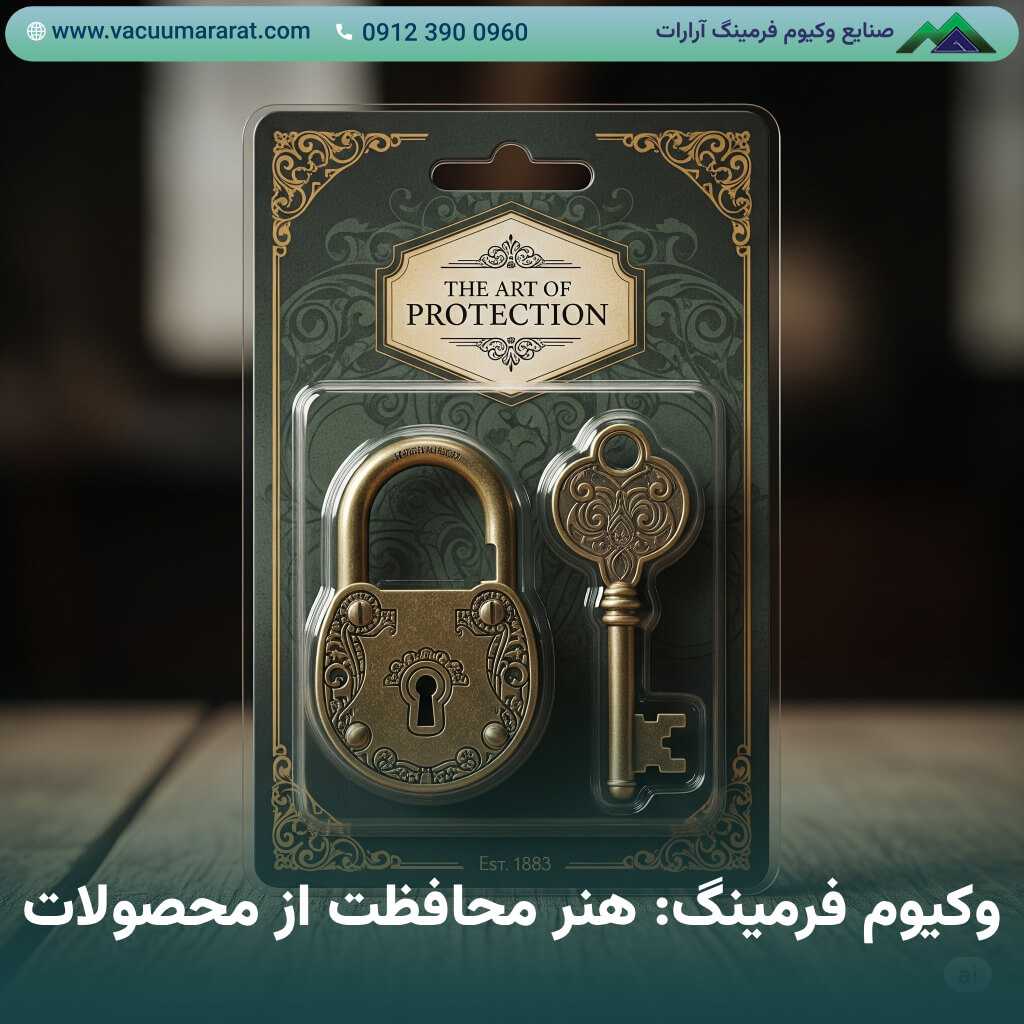

در دنیای رقابتی امروز، بستهبندی نقشی فراتر از یک پوشش ساده ایفا میکند؛ این یک سپر محافظتی هوشمند و ابزاری قدرتمند برای بازاریابی و برندسازی است. یک بستهبندی جذاب و باکیفیت میتواند محصول شما را متمایز کرده و تجربه مشتری را بهبود بخشد، در حالی که محافظت از محصول در برابر آسیبها، رطوبت و گرد و غبار از اهمیت بالایی برخوردار است.

در این میان، وکیوم فرمینگ به عنوان یک هنر و علم، مفهوم حفاظت از محصول را به سطحی نوین ارتقا بخشیده است. این تکنیک، با ترکیب ظرافت مهندسی و زیباییشناسی، بستهبندیهایی خلق میکند که نه تنها ایمنی محصول را تضمین میکنند، بلکه جلوهای زیبا و دلنشین به آن میبخشند. صنایع وکیوم فرمینگ آرارات با بیش از ۲۵ سال تجربه، دانش فنی و بهرهگیری از تکنولوژیهای نوین و تجهیزات پیشرفته، در این حوزه پیشرو بوده و خدمات باکیفیتی را ارائه میدهد.

فهرست محتوا

وکیوم فرمینگ چیست؟

وکیوم فرمینگ یک روش پرکاربرد و مقرونبهصرفه برای شکلدهی ورقهای ترموپلاستیک است که به دلیل سرعت بالای تولید، هزینه پایین قالبسازی و قابلیت شکلدهی متنوع، جایگاه ویژهای در صنعت دارد.

فناوری وکیوم فرمینگ (Vacuum Forming) یک روش پیشرفته در شکلدهی حرارتی است. در این فرآیند، یک ورق از مواد ترموپلاستیک تا دمای مشخصی حرارت داده میشود تا نرم و انعطافپذیر شود. سپس، با استفاده از قالب و مکش خلأ (تخلیه هوای محبوس شده بین ورق و قالب)، ورق پلاستیکی شکل قالب را به خود میگیرد. این فرآیند به دلیل سرعت تولید بالا، انعطافپذیری در طراحی، کیفیت ساخت بالا و صرفهجویی در هزینهها، انتخابی محبوب در بین تولیدکنندگان صنایع مختلف است. کاربردهای وکیوم فرمینگ فراتر از بستهبندی شامل تولید قطعات پلاستیکی در صنایع خودروسازی، هواپیماسازی، بدنهی دستگاهها و تجهیزات، قایقسازی، لوازم خانگی و قطعات محافظ است.

بستهبندی وکیوم فرمینگ چیست؟

بستهبندی وکیوم فرمینگ نوعی بستهبندی پلاستیکی شکلدهی شده و اغلب به صورت طلق شفاف و مات است که با استفاده از مواد ترموپلاستیک ساخته میشود. این بستهبندی نه تنها محصول را به خوبی در برابر گرد و غبار، رطوبت و آسیبهای فیزیکی محافظت میکند، بلکه با قابلیت شفاف بودن، به مشتری این امکان را میدهد که محصول را قبل از خرید مشاهده کند. این ویژگی میتواند در افزایش فروش و ایجاد اعتماد در مشتری مؤثر باشد.

بستهبندی وکیوم فرمینگ دارای انعطافپذیری بسیار بالایی در طراحی است و میتوان آن را تقریباً به هر شکل دلخواهی تولید کرد. همچنین، این نوع بستهبندی میتواند با کارتها و جعبههای مقوایی چاپ شده ادغام شود. در ادامه به انواع بستهبندیهای وکیوم فرمینگ خواهیم پرداخت.

انواع بستهبندی وکیوم فرمینگ و روشهای مهر و موم

بستهبندیهای وکیوم فرمینگ به دلیل تنوع بالا و انعطافپذیری در طراحی، در قالبهای گوناگون و با روشهای مهر و موم متنوعی تولید میشوند. هر نوع، بسته به ماهیت محصول و نیازهای حفاظتی آن، ویژگیهای خاص خود را دارد:

این نوع شامل یک قطعه پلاستیکی شفاف فرمدهیشده (بلیستر وکیومی) و یک کارت مقوایی چاپی است که دارای چسب بلیستر است. محصول درون قطعه وکیومی قرار گرفته و سپس قطعه روی کارت مقوایی قرار گرفته و با دستگاه پرس حرارتی به صورت محکم چسبانده میشود. معمولاً در بالای این بستهبندی یک سوراخ برای آویزان کردن در فروشگاه ایجاد میشود.

مزایا: نمایش شفاف محصول، امنیت قابل قبول، محافظت در برابر ضربه و رطوبت، ارائه اطلاعات روی کارت چاپی، تولید اقتصادی.

کاربردها: لوازم الکترونیکی کوچک، لوازم آرایشی و بهداشتی، لوازم تحریر، اسباببازیها، ابزارآلات و قطعات یدکی خودرو.

ساختاری شبیه به بلیستر پرسی دارد اما از یک قطعه وکیومی و دو کارت مقوایی استفاده میشود. قطعه وکیومی بین دو کارت چاپی قرار گرفته و با دستگاه پرس حرارتی به هم چسبانده میشود. یکی از کارتها دارای یک برش پنجرهای است که قسمت برجسته وکیوم از آن بیرون میآید و محصول را نمایش میدهد.

مزایا: امکان ارائه گرافیک بیشتر و تبلیغات جذابتر، امنیت بالاتر.

کاربردها: ابزارآلات، لوازم جانبی الکترونیکی، تجهیزات یدکی و اقلامی که نیاز به اطلاعات چاپی گسترده دارند.

یک قطعه وکیومی شفاف با سه لبه خم شده یا تا شده دارد که فضای مناسب برای قرارگیری یک کارت مقوایی را فراهم میکند. کارت مقوایی به صورت کشویی درون این قطعه وکیومی قرار میگیرد. معمولاً دارای سوراخ آویز برای نمایش در فروشگاه است.

مزایا: باز و بسته شدن آسان، شفافیت بالا، امکان چاپ اطلاعات روی کارت، قابلیت شخصیسازی.

کاربردها: لوازم الکترونیکی، آرایشی و بهداشتی، اسباببازیها، ابزارآلات، لوازم یدکی خودرو و لوازم تحریر.

این بستهبندی از دو قطعه وکیومی شفاف و معمولاً یک کارت چاپی در بین آنها تشکیل شده است. لبههای دو قطعه وکیوم با استفاده از دستگاه جوش هایفرکانس (امواج فرکانس بالا) به یکدیگر جوش داده میشوند تا اتصال محکم و بادوامی ایجاد شود. متریال این بستهبندی باید از جنس PVC باشد تا قابلیت جوش خوردن را داشته باشد.

مزایا: امنیت بسیار بالا در برابر دستکاری و تقلب (تقریباً غیرممکن است بدون تخریب باز شود)، محافظت عالی، شفافیت، قابلیت سفارشیسازی.

کاربردها: محصولات آرایشی و بهداشتی، ابزارآلات کوچک و متوسط، محصولات الکترونیکی، لوازم پزشکی و دارویی، و محصولات غذایی خاص و گرانبها که نیاز به امنیت و حفاظت بیشتر دارند.

شامل یک قطعه وکیوم فرمینگ استند (پلاستیکی شکلدهی شده) است که به عنوان مقسم یا نگهدارنده داخل یک جعبه مقوایی دربدار قرار میگیرد. جعبه میتواند دارای پنجره شفاف روی درب باشد تا محصول قابل مشاهده باشد.

مزایا: طراحی شیک و حرفهای، شفافیت و نمایش محصول، چاپ سفارشی روی جعبه، کاربردپذیری بالا برای محصولات چندگانه، محافظت عالی از محصول.

کاربردها: بستهبندی شکلات و خوراکیهای کادویی، ستهای آرایشی، مجموعههای بازی، ابزارهای چندقطعهای، قطعات صنعتی.

یک قطعه وکیوم فرمینگ به شکل استند یا هولدر است که به صورت مستقل و بدون نیاز به تکیهگاه اضافی عمل میکند. برای نگهداشتن و نمایش محصولات به صورت گروهی طراحی شده است.

مزایا: نمایش منظم و حرفهای، پایداری و استقلال، نگهداشتن گروهی محصولات، مقرونبهصرفه، استفاده از مواد اولیه قابل بازیافت.

کاربردها: نمایش گروهی محصولات آرایشی و بهداشتی، لوازم پزشکی و آزمایشگاهی، اسباببازیها و قطعات صنعتی و الکترونیکی در فروشگاهها و داروخانهها.

شامل یک قطعه وکیوم یکپارچه دو قسمتی (محفظه و درب) است که به صورت لولایی یا تاشو به هم متصل هستند. درب و محفظه دارای فرورفتگی و برجستگیهایی هستند که برای چفت کردن و قفل شدن یکدیگر طراحی شدهاند. این نوع بستهبندی قابلیت استفاده مجدد دارد.

مزایا: استفاده آسان، چفت شدن محکم درب، نمایش کامل محصول (شفافیت)، جلوگیری از ورود گرد و غبار، قابلیت بازیافت.

کاربردها: بستهبندی محصولات شکننده مانند تخممرغ و تخم بلدرچین، خشکبار، میوه و سبزیجات، گوشت و فرآوردههای گوشتی.

این نوع نیز دارای دو بخش محفظه و پوشش پشتی به صورت لولایی یا تاشو است. میتوان پوشش یا درب پشتی را به صورت چفتی یا با جوش هایفرکانس به قسمت محفظه مهر و موم کرد. امکان استفاده از کارت مقوایی در داخل بستهبندی نیز وجود دارد.

مزایا: شفافیت و نمایش محصول، امنیت عالی (با مهر و موم هایفرکانس)، باز و بسته شدن آسان (با مهر و موم چفتی)، امکان استفاده از کارت مقوایی چاپی، سهولت مونتاژ.

کاربردها: لوازم الکترونیکی، لوازم آرایشی-بهداشتی، لوازم جانبی، اسباببازی، قطعات یدکی و لوازم تحریر.

شامل یک محفظه مات یا شفاف و مقاوم و یک درب جداگانه است که به صورت چفتی بر روی محفظه قرار میگیرد. این نوع را گاهی “زیره و رویه” نیز مینامند.

مزایا: امکان تقسیمبندی محفظه، شفافیت و نمایش محصول، باز و بسته شدن آسان، امکان سفارشیسازی بالا، استفاده مجدد، استفاده از مواد اولیه بهداشتی و دارای گرید غذایی.

کاربردها: بستهبندی خشکبار، میوه خشک، مواد غذایی آماده، سرو سالاد و مواد غذایی در رستورانها، و سایر محصولات.

این نوع شبیه به یک ظرف سینیشکل است که محصول درون آن قرار میگیرد. سپس برای پوشش و بستن آن از یک لایه پوششی پلاستیکی یا فویلی بر روی دهانه ظرف استفاده و سیل (مهر و موم) میشود. لبههای ظرف باید صاف، پهن و ضخیم باشند تا فرآیند سیل به درستی انجام شود.

مزایا: افزایش ماندگاری، حفظ طراوت، بهداشتی بودن، ظاهر جذاب، شفافیت، مانع ورود آلودگی، اکسیژن و رطوبت.

کاربردها: بستهبندی لبنیات، گوشت قرمز، گوشت مرغ، محصولات گوشتی فرآوریشده، مواد غذایی آماده و نیمهآماده، محصولات دریایی (ماهی و میگو)، قارچ، میوه و میوه خشک.

یک روش منحصربهفرد که بدون نیاز به قالب آلومینیومی عمل میکند. محصول روی یک کارت مقوایی چیده میشود و سپس یک ورق پلاستیکی گرمشده مستقیماً روی محصول و کارت قرار گرفته و با ایجاد خلاء، دقیقاً به فرم آن شکل میگیرد و مانند پوسته پوششی، کل محصول را میپوشاند. برای اتصال قوی، سطح کارت مقوایی به چسب مخصوص آغشته میشود.

مزایا: مقرونبهصرفه بودن (حذف هزینه قالبسازی)، شفافیت بالا، حفظ ایمنی و کیفیت محصول، دوام بالا، قابلیت آویزان کردن.

کاربردها: بستهبندی قطعات صنعتی، اسباببازیها، ابزارآلات و دیگر محصولات.

کاربردهای گسترده بستهبندی وکیوم فرمینگ

۱. بستهبندی کالاهای مصرفی

لوازم آرایشی و بهداشتی، لوازم الکترونیکی و لوازم جانبی، ابزارآلات و قطعات صنعتی، اسباببازی، لوازم تحریر، محصولات فانتزی و هدایا.

۲. بستهبندی مواد غذایی

شیرینی و شکلات، تخممرغ و تخم بلدرچین, میوه و سبزیجات, گوشت و فرآوردههای گوشتی, لبنیات (ماست، پنیر), قارچ, خشکبار و آجیل, مواد غذایی آماده و نیمهآماده, چاشنیها.

۳. تولید ظروف یکبار مصرف

لیوانها، بشقابها و کاسههای یکبار مصرف, ظروف دربدار, ظروف قابل سیل, ظروف نگهدارنده.

۴. صنایع پزشکی و دارویی

بستهبندی اقلام پزشکی و جراحی, ظروف و سینیهای دندانپزشکی و اتاق عمل, بستهبندی داروها (بلیستر پک).

مزایای بستهبندی وکیوم فرمینگ

وکیوم فرمینگ، به عنوان یک روش پرکاربرد و مقرونبهصرفه برای شکلدهی ورقهای ترموپلاستیک، مزایای متعددی در صنعت بستهبندی و تولید قطعات پلاستیکی ارائه میدهد. این مزایا، وکیوم فرمینگ را به یک انتخاب هوشمندانه و مؤثر برای تولیدکنندگان در صنایع گوناگون تبدیل کرده است.

در ادامه به توضیح مزایای اصلی وکیوم فرمینگ میپردازیم:

۱. محافظت جامع و امنیت بالا

محافظت فیزیکی عالی: بستهبندیهای وکیوم فرمینگ، محصول را کاملاً در بر میگیرند و از آن در برابر ضربات، لرزش، فشار، گرد و غبار، رطوبت و آلودگیها محافظت میکنند. با به حداقل رساندن فضای خالی درون بستهبندی، از جابجایی و اصطکاک محصول جلوگیری میشود.

افزایش امنیت: بستهبندیهایی که با روشهایی مانند پرس حرارتی، جوش هایفرکانس و سیل مهر و موم میشوند، امنیت بالایی دارند و هرگونه تلاش برای دستکاری یا تقلب در آنها به وضوح مشخص میشود. این ویژگی، از سرقت محصولات کوچک در خردهفروشیها نیز جلوگیری میکند.

افزایش ماندگاری و حفظ کیفیت: با حفظ تازگی و کیفیت محصول و جلوگیری از اکسیداسیون، عمر مفید محصول افزایش مییابد. این فرآیند از ورود آلودگیها، اکسیژن و رطوبت جلوگیری کرده و به حفظ طراوت، طعم و بوی محصول کمک میکند.

بهداشتی بودن: استفاده از مواد اولیه با گرید بهداشتی (Food Grade) مانند PET و HIPS، سلامت محصول را تضمین میکند و برای بستهبندی مواد خوراکی الزامی است.

۲. مقرون به صرفه بودن و بهینهسازی منابع

هزینه پایین تولید: وکیوم فرمینگ یکی از روشهای اقتصادی و کمهزینه برای تولید بستهبندی است. هزینه پایین قالبسازی، بهویژه برای نمونهسازی (با قالبهای چوبی یا پرینت سهبعدی) و عدم نیاز به ابزارهای پیچیده، به کاهش هزینهها کمک میکند.

کاهش هزینههای لجستیک: کاهش حجم بستهبندی و وزن سبکتر محصولات، هزینههای حمل و نقل و انبارداری را به طور قابل توجهی کاهش میدهد.

بهینهسازی مواد: طراحی دقیق منجر به کاهش ضایعات محصول و بهینهسازی مصرف مواد اولیه میشود.

۳. جذابیت بصری، شفافیت و ارتقاء برند

نمایش جذاب محصول: بستهبندیهای وکیوم فرمینگ اغلب شفاف هستند که امکان مشاهده مستقیم و کامل محصول را برای مشتریان فراهم میکند. این شفافیت به افزایش اعتماد مشتری و ترغیب به خرید کمک شایانی میکند.

طراحی حرفهای: طراحی شیک، حرفهای و بصری جذاب به محصول جلوهای لوکس میبخشد و آن را در قفسههای فروشگاهها متمایز میکند.

فرصتهای برندینگ: امکان چاپ سفارشی روی کارتهای مقوایی (در انواع بلیستر، کشویی و هایفرکانس) یا حتی روی خود قطعه وکیومی، به ارائه اطلاعات کامل محصول، تبلیغ برند و افزایش شناخت آن کمک میکند.

وفاداری مشتری: تجربه مثبت مشتری و بستهبندی ایمن و جذاب، به ارتقاء برند و وفاداری مشتریان منجر میشود.

قابلیت نمایش: بستهبندیها میتوانند به گونهای طراحی شوند که قابلیت نگهداری در استندهای فروشگاهی یا به صورت آویزدار باشند، که نمایش منظم و جذاب محصولات را تسهیل میکند.

۴. انعطافپذیری و قابلیت سفارشیسازی بالا

تنوع در شکلدهی: این روش قابلیت شکلدهی متنوع و تولید قطعات و بستهبندیهایی با هر شکل، اندازه و ضخامت را دارد.

طراحی دقیق قالب: امکان طراحی دقیق و مهندسیشده قالب متناسب با جزئیات محصول و هویت برند وجود دارد.

راهحلهای منحصربهفرد: وکیوم فرمینگ راهحلهای سفارشی و منحصربهفردی برای محصولات مختلف، حتی با اشکال پیچیده یا حساس، ارائه میدهد.

نمونهسازی سریع: امکان تولید نمونههای اولیه و اصلاح طراحی قبل از تولید انبوه، هزینهها و زمان توسعه محصول را کاهش میدهد.

۵. پایداری و مسئولیتپذیری زیستمحیطی

قابلیت بازیافت: بسیاری از مواد اولیه پرکاربرد مانند PET و HIPS قابل بازیافت هستند؛ PVC نیز در شرایط خاص قابل بازیافت است.

کاهش ردپای زیستمحیطی: استفاده بهینه از مواد و کاهش نیاز به مواد پرکننده اضافی، ضایعات زیستمحیطی را کاهش داده و به حفظ منابع طبیعی و کاهش ردپای کربن کمک میکند.

۶. سهولت و کارایی در فرآیند و استفاده

سرعت بالای تولید: وکیوم فرمینگ یکی از سریعترین روشهای تولید است.

دقت بالا: دقت بالا در شکلدهی، فرآیند را کارآمد و با خطای کمتر میسازد.

سهولت در استفاده: بستهبندیهایی مانند انواع تاشو/صدفی و کشویی امکان باز و بسته شدن آسان و مکرر را فراهم میکنند که تجربه کاربری را بهبود میبخشد. مونتاژ نیز به دلیل سادگی فرآیند، آسان است.

وزن سبک: محصولات تولیدی با این روش سبک وزن هستند.

کارایی قالب: قالبهای آلومینیومی به دلیل وزن سبک و دفع حرارت سریع، به افزایش کارایی فرآیند کمک میکنند.

فرآیند تولید بستهبندی وکیوم فرمینگ

تولید بستهبندی وکیوم فرمینگ یک فرآیند دقیق و چند مرحلهای است که از طراحی اولیه تا تحویل نهایی به مشتری را شامل میشود. این مراحل در سه بخش اصلی خلاصه میشوند:

بخش اول: مراحل اولیه (طراحی و آمادهسازی)

۱. بررسی محصول

ابتدا محصول مورد نظر از نظر ابعاد، وزن، شکل هندسی، حساسیت و کاربری نهایی به دقت بررسی میشود. این اطلاعات پایه انتخاب مواد اولیه و طراحی قالب را فراهم میسازند.

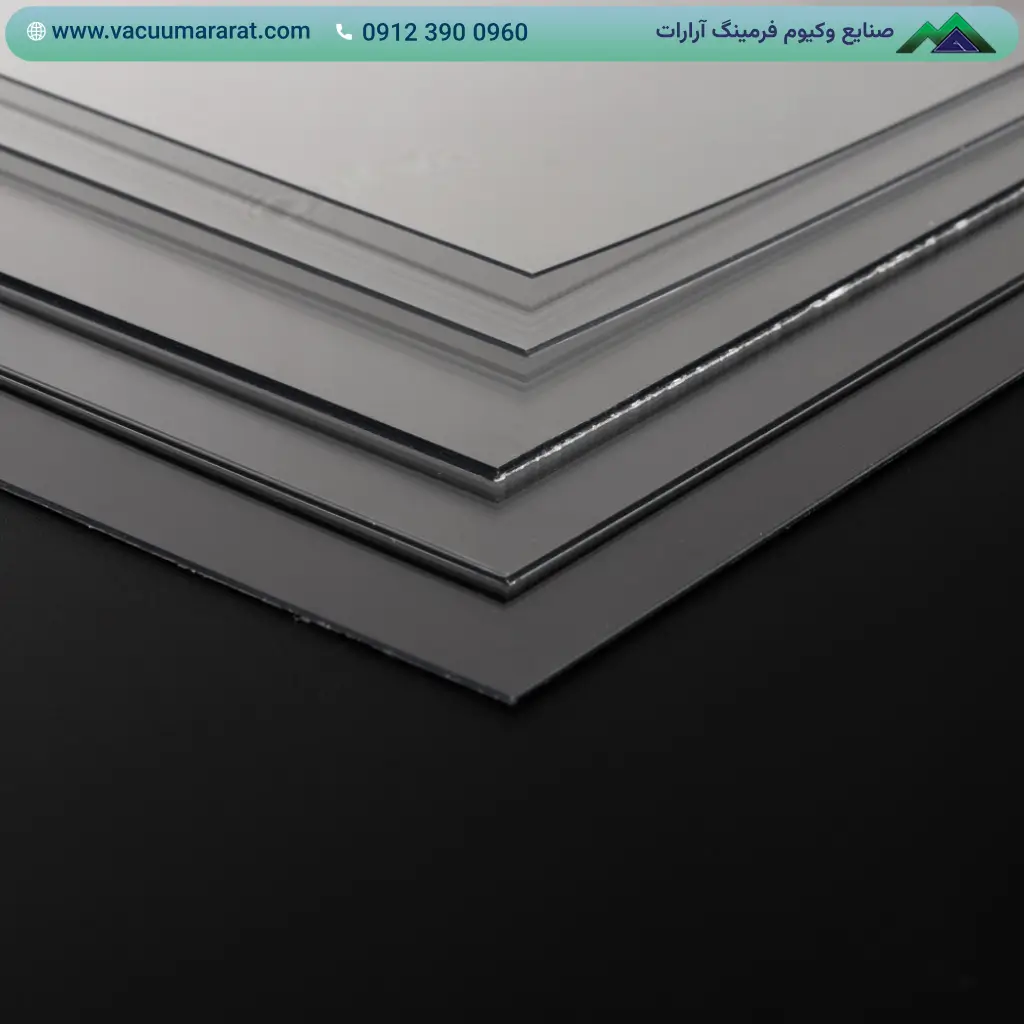

۲. انتخاب مواد اولیه (ورق)

نوع ورق پلاستیکی (ترموپلاستیک) باید متناسب با کاربرد نهایی و ویژگیهای محصول (مثلاً گرید خوراکی برای مواد غذایی، ضخامت کافی برای نسبت کشش) انتخاب شود. یکنواختی ضخامت ورق نیز اهمیت بالایی دارد.

۳. طراحی سهبعدی قالب

بر اساس اطلاعات محصول و مواد اولیه، طراحی سهبعدی قالب وکیوم فرمینگ با نرمافزارهای تخصصی (مانند CAD) انجام میشود. این طراحی باید زاویه خروج (Draft Angle) مناسب برای جداسازی آسان قطعه و مسیرهای تخلیه هوا (Venting) در نقاط حساس قالب را شامل شود.

بخش دوم: فرآیند اصلی وکیوم فرمینگ (شکلدهی)

۱. ساخت قالب

قالبهای وکیوم فرمینگ معمولاً از آلومینیوم برای تولید انبوه (به دلیل هدایت حرارتی بهتر و دوام بیشتر) یا چوب، رزین اپوکسی یا پرینت سهبعدی برای نمونهسازی و تست طراحی ساخته میشوند. دستگاه CNC نقش کلیدی در ساخت قالبهای دقیق دارد.

۲. بستن قالب و قرار دادن ورق

قالب به طور محکم بر روی قالببند دستگاه وکیوم فرمینگ نصب میشود. سپس رول یا شیت ورق پلاستیکی در قسمت ورقگیر دستگاه قرار میگیرد.

۳. گرمایش ورق

ورق پلاستیکی توسط هیترهای دستگاه (ترجیحاً هیترهای Zoned برای کنترل یکنواخت دما) تا دمای شکلپذیری خود گرم میشود. کنترل دقیق دما حیاتی است؛ گرم شدن بیش از حد باعث افتادگی و نازک شدن موضعی و تغییر رنگ میشود، و گرم شدن ناکافی منجر به شکلگیری ناقص و چروکیدگی میگردد. استفاده از سنسورهای مادون قرمز (IR) برای پایش دقیق دما توصیه میشود.

۴. شکلدهی (وکیوم)

پس از نرم شدن، قالب بالا میآید و به ورق میچسبد. سپس پمپ وکیوم با مکش سریع و کامل هوا از بین ورق و قالب، باعث میشود که ورق شکل قالب را به خود بگیرد. «سرعت دستیابی به خلأ» و «پایداری آن» مهمتر از فشار نهایی خلأ است.

۵. خنکسازی و جداسازی

قطعه شکل گرفته باید به اندازه کافی روی قالب بماند تا خنک و سخت شود. خنکسازی صحیح باعث تثبیت شکل نهایی و جلوگیری از اعوجاج یا تغییر شکل پس از جداسازی میشود. از آب و هوای فشرده خنککننده میتوان استفاده کرد. جدا کردن زودهنگام منجر به اعوجاج و چروکخوردگی میشود.

۶. برش قطعه شکلدهی شده

در پایان، قطعه شکلدهی شده توسط کاتر دستگاه برش داده میشود تا از رول یا شیت جدا شود.

بخش سوم: مراحل پایانی (پسفرمینگ و کنترل کیفیت)

۱. برش اضافات و پرداخت نهایی

پس از شکلدهی و خنکسازی، برش دقیق لبهها و حذف اضافات ورق (Trim Allowance) برای دستیابی به ظاهر نهایی مطلوب حیاتی است. این کار معمولاً با قالب برش مکانیکی (دایکات) یا برش CNC انجام میشود. لبههای تیز و ناهموار میتواند به مشتری آسیب برساند.

۲. مونتاژ و بستهبندی

بسته به نوع بستهبندی، قطعات مختلف ممکن است مونتاژ شوند (مانند قرار دادن محصول درون قطعه وکیومی، چسباندن به کارت مقوایی، یا جوش دادن قطعات).

۳. کنترل کیفیت

برای اطمینان از کیفیت پایدار و تکرارپذیر، یک برنامه جامع کنترل کیفیت (QC) باید در تمامی مراحل تولید اجرا شود. این شامل بازرسی بصری (بررسی حباب، چینخوردگی، سوختگی، تغییر رنگ)، اندازهگیری ابعادی و ضخامت در نقاط بحرانی، آزمون فیت و کارکرد محصول، و ثبت و تحلیل دادههای تولید (SPC) است.

۴. ارسال به مشتری

پس از تایید نهایی کیفیت، بستهبندیها آماده ارسال به مشتری میشوند.

مواد اولیه مورد استفاده در وکیوم فرمینگ

مواد اولیه مورد استفاده در وکیوم فرمینگ از نوع ترموپلاستیک (گرمانرم) هستند که با حرارت نرم و شکلپذیر شده و پس از خنک شدن دوباره سفت میشوند. انتخاب صحیح مواد اولیه، تأثیر مستقیمی بر ویژگیهای مکانیکی، حرارتی، ظاهری و کیفیت نهایی بستهبندی دارد.

۱. PET (پلیاتیلن ترفتالات)

ویژگیها: شفافیت بسیار بالا، مقاومت شیمیایی خوب، مقاومت مکانیکی بالا در برابر ضربه و پارگی، قابل بازیافت و دوستدار محیط زیست، وزن سبک، مقاومت به رطوبت و اکسیژن. حساسیت بالایی به گرما دارد و نیازمند کنترل دقیق دمای گرمایش است.

کاربردها: انتخابی ایدهآل برای بستهبندی مواد غذایی و دارویی (دارای گرید خوراکی)، نوشیدنیها، محصولات بهداشتی و آرایشی.

۲. PVC (پلیوینیل کلراید)

ویژگیها: شفاف، ارزان و بسیار شکلپذیر، مقاومت بالا در برابر رطوبت، روغن، مواد شیمیایی و حریق، دوام مکانیکی بالا، انعطافپذیری خوب. قابلیت جوش خوردن با امواج فرکانس بالا (هایفرکانس) را دارد.

کاربردها: بستهبندی برخی کالاهای مصرفی مانند وسایل الکترونیکی، ابزارآلات و اسباببازیها. در بستهبندیهای هایفرکانس ضروری است.

۳. HIPS (پلیاستایرن مقاوم به ضربه – هایمپک)

ویژگیها: مقاومت ضربهای مناسب، سطحی مات یا نیمهشفاف، هزینه پایین، شکلپذیری آسان، قابلیت رنگپذیری و آنتیاستاتیک. دارای گرید بهداشتی.

کاربردها: بستهبندیهای صنعتی که شفافیت در اولویت نیست، ظروف یکبار مصرف (فستفود)، سینیهای نگهدارنده قطعات داخل جعبه، محصولات پزشکی و لوازم آرایشی و بهداشتی.

۴. ABS (آکریلونیتریل بوتادین استایرن)

ویژگیها: مقاوم و بادوام، مقاومت بسیار بالا در برابر ضربه و خراش و دمای بالا، پایداری ابعادی و مکانیکی فوقالعاده، کیفیت سطح عالی و پایداری رنگ. از دیگر مواد گرانتر است و بیشتر برای قطعات ضخیم استفاده میشود.

کاربردها: عمدتاً در بستهبندیهای صنعتی و قطعات محافظ، ساخت قطعات ضخیم وکیوم فرمینگ، لوازم خانگی، کلاه ایمنی، دیواره دستگاههای الکترونیکی، قطعات داخلی یخچال و پانلهای دیوارپوش.

۵. مقوا

ویژگیها: هرچند پلاستیکی نیست، اما در بسیاری از بستهبندیهای ترکیبی وکیوم (مانند بلیسترها و استندهای جعبهای) نقش مکمل مهمی دارد. قابل بازیافت و زیستتخریبپذیر، مناسب برای چاپ با کیفیت بالا، قیمت مناسب و استحکام نسبی.

کاربردها: بستر نگهدارنده برای قطعات وکیومی در جعبهها و بلیستر پکها، ارائه اطلاعات محصول و برندینگ.

نکات حیاتی در انتخاب ورق

همواره گرید مواد را متناسب با کاربرد نهایی (مثلاً گرید خوراکی) انتخاب کنید و از گواهیهای لازم اطمینان حاصل کنید.

ضخامت اولیه ورق را با دقت و با توجه به نسبت کشش (Draw Ratio) محاسبه کنید تا ضخامت نهایی در نقاط حساس کافی باشد.

یکنواختی ضخامت ورق اهمیت بسیار زیادی دارد؛ نوسان بیش از ±۵٪ میتواند منجر به نازک شدن ناهمگون شود.

دادهبرگه فنی (TDS) ارائهشده توسط تأمینکننده ماده (شامل محدوده دمای نرم شدن و ضریب کشش مجاز) را حتماً بررسی کنید.

برای بستهبندیهای شفاف، مادهای را انتخاب کنید که در محدوده دمایی دستگاه شما پایدار بماند و مقاومت حرارتی لازم را داشته باشد.

قالب وکیوم فرمینگ، انواع و متریال آن

طراحی و ساخت قالب وکیوم فرمینگ، مهمترین بخش فرآیند وکیوم فرمینگ است. قالب در واقع شیء فیزیکی است که طرح مورد نظر بر اساس آن ساخته میشود تا برای شکلدهی به مواد ترموپلاستیک در فرآیند خلأ استفاده شود. شکل نهایی و دقیق بستهبندی محصول به وسیله قالب ایجاد میشود.

طراحی و ساخت قالب وکیوم فرمینگ

بدون قالب، امکان شکلدهی به ترموپلاستیکها وجود ندارد و بنابراین قالب از اهمیت بالایی برخوردار است. برای تولید محصول باکیفیت و با ثبات، قالب باید به صورت استاندارد طراحی شود تا در طول فرآیند حرارت و سرما شکل و ثبات خود را از دست ندهد.

مراحل اصلی طراحی و ساخت قالب به شرح زیر است:

- بررسی محصول: ابتدا ابعاد، وزن، شکل، حساسیتها و نیازهای حفاظتی محصول بهدقت بررسی میشود تا اطلاعات لازم برای طراحی قالب و انتخاب نوع ورق پلاستیکی به دست آید.

- طراحی سهبعدی: پس از بررسی، مدل سهبعدی قالب با استفاده از نرمافزارهای تخصصی مانند CAD طراحی میشود. در طراحی قالب، جزئیاتی مانند ابعاد دقیق محصول، محل قرارگیری قطعات مختلف و فضای لازم برای جلوگیری از جابجایی محصول در نظر گرفته میشود.

- تولید با دستگاه CNC: پس از نهایی شدن طرح، قالب وکیوم فرمینگ با استفاده از دستگاه CNC (کنترل عددی کامپیوتری) ساخته میشود. دستگاه CNC به دلیل دقت بالا در برش و حکاکی، به تولید قالبهای دقیق و باکیفیت کمک میکند و تضمین میکند که تمامی جزئیات محصول پوشش داده شود.

نکات حیاتی در طراحی قالب:

- قالب باید دارای زاویه خروج (Draft Angle) مناسب (حداقل 3 تا 5 درجه) باشد تا قطعه بهراحتی از آن جدا شود.

- طراحی باید شامل مسیرهای تخلیه هوا (Venting) مانند سوراخها یا شیارهای ریز در نقاط عمیق و گوشهها باشد تا هوا بهطور کامل تخلیه شده و از تشکیل حباب جلوگیری شود.

- سطح قالب باید صیقلی باشد و از شعاعهای انتقال (انحنا) به جای لبههای تیز در طراحی هندسی قالب استفاده شود تا به

متریال قالب وکیوم فرمینگ

متریال قالب به مواد مورد استفاده در ساخت آن اشاره دارد که معمولاً شامل آلومینیوم، چوب، امدیاف و… است. در ایران بیشتر از آلومینیوم و چوب استفاده میشود.

متریال | کاربرد اصلی | مزایا و ویژگیها | روش ساخت |

آلومینیوم | تولید انبوه و تیراژ بالا، قطعات دقیق و بزرگتر. | مقاومت و استحکام بالا، ثبات، وزن سبک، دفع مؤثر گرما در فرآیند، هدایت حرارتی بهتر. | ساخت با دستگاه CNC یا ریختهگری (که کمتر رایج است). |

چوب/امدیاف | ساخت نمونههای اولیه و تست طراحی. | هزینه ساخت کم و فرآیند ساخت آسان. | با ابزارهای ساده نجاری یا دستگاه CNC. |

نکات مهم: قالبهای چوبی به دلیل استحکام و ثبات کم، برای تولیدات گسترده مناسب نیستند، زیرا در چرخه سرما و گرما منبسط و منقبض شده و ممکن است ترک بخورند. برای نمونهسازی و تستهای اولیه میتوان از قالبهای ساخته شده با رزین اپوکسی یا تکنولوژی پرینت سهبعدی نیز استفاده کرد.

انواع قالب از نظر ساختار

قالبهای وکیوم فرمینگ بسته به نوع بستهبندی نهایی، میتوانند اشکال متفاوتی داشته باشند:

- قالبهای یک تکه (استاندارد): این قالبها برای تولید انواع بستهبندیهایی که از یک قطعه پلاستیکی فرمدهی شده تشکیل میشوند (مانند بلیستر پرسی، کشویی، استندها و ظروف سینیشکل) به کار میروند.

- قالبهای دو تکه (نری و مادگی): این قالبها برای شکلدهی به بستهبندیهای دو طرفه مانند

دستگاههای مورد استفاده در فرایند وکیوم فرمینگ

فرآیند تولید بستهبندیهای وکیوم فرمینگ و قطعات پلاستیکی نیازمند مجموعهای از دستگاهها و تجهیزات تخصصی است که هر یک در مراحل مختلف تولید، از ساخت قالب تا مونتاژ نهایی، نقش حیاتی ایفا میکنند.

مهمترین دستگاههای مورد استفاده در این صنعت عبارتند از:

۱. دستگاه وکیوم فرمینگ (Vacuum Forming Machine)

دستگاه وکیوم فرمینگ، ابزار اصلی برای شکلدهی ورقهای ترموپلاستیک است. این دستگاه ورق پلاستیکی را تا دمای مشخص گرم کرده و سپس با استفاده از مکش خلاء (تخلیه هوا)، آن را به شکل قالب مورد نظر فرم میدهد. این دستگاهها به طور کلی به دو دسته نیمه اتوماتیک و اتوماتیک تقسیم میشوند.

۱.۱. دستگاه وکیوم فرمینگ نیمه اتوماتیک

دستگاههای نیمه اتوماتیک معمولاً در ابعاد کوچکتری ساخته میشوند و عملکرد رضایتبخشی دارند.

- روش تغذیه و عملکرد: این دستگاهها با شیتهای ورق پلاستیکی تغذیه میشوند.

- سرعت و اپراتوری: سرعت تولید و شکلدهی در آنها پایینتر است و برای تولیدات انبوه چندان مناسب نیستند، زیرا نیاز به دخالت مستقیم اپراتور دارند.

- مراحل کار: شامل بستن قالب، قرار دادن شیت پلاستیکی، روشن کردن هیتر و حرارتدهی توسط اپراتور، بالا آمدن قالب و انجام فرآیند وکیوم فرمینگ، سرد کردن قطعه و در نهایت برش آن توسط کاتر دستگاه است.

۱.۲. دستگاه وکیوم فرمینگ اتوماتیک

این دستگاهها برای تولیدات با حجم بالا و تیراژ گسترده طراحی شدهاند.

- روش تغذیه و عملکرد: این دستگاهها با رول پلاستیکی تغذیه میشوند. این دستگاهها شامل بخشهای مختلفی همچون قالببند، هیتر، خنککننده، پمپ خلاء، کاتر و نگهدارنده رول پلاستیکی هستند.

- سرعت و اپراتور: سرعت تولید و شکلدهی در دستگاههای اتوماتیک بسیار بالاست و نیاز به دخالت کمتری از سوی اپراتور دارند.

- مراحل کار: تمامی مراحل اصلی شامل حرارتدهی، شکلدهی، خنک کردن و برش قطعه شکلگرفته بهطور خودکار توسط دستگاه انجام میشود.

۲. دستگاه پرس حرارتی (Blister Press Machine)

دستگاه پرس حرارتی، که گاهی به آن دستگاه پرس بلیستر نیز گفته میشود، یک دستگاه تخصصی برای مونتاژ نهایی در انواع خاصی از بستهبندیها است.

- کاربرد: این دستگاه برای تکمیل بستهبندیهای بلیستر پرسی و بلیستر میان کارتی استفاده میشود.

- نحوه عملکرد: دستگاه پرس حرارتی با اعمال فشار و حرارت، چسب بلیستر که روی کارت مقوایی قرار دارد را فعال میکند. این فرآیند باعث میشود که قطعه وکیوم فرمینگ به صورت محکم و پایدار به کارت مقوایی چسبانده شود.

- نقش در فرآیند تولید: استفاده از این دستگاه باعث میشود که فرآیند مونتاژ بستهبندی بلیستر میان کارتی با سرعت بالایی انجام پذیرد.

۳. دستگاه جوش هایفرکانس (High-Frequency Welding Machine)

دستگاه جوش هایفرکانس در فرآیند بستهبندیهایی که نیاز به امنیت و استحکام بالا دارند، کاربرد دارد.

- کاربرد: این دستگاه برای تولید بستهبندیهای وکیوم فرمینگ هایفرکانس استفاده میشود.

- نحوه عملکرد: دستگاه با استفاده از امواج فرکانس بالا (High-Frequency) و حرارت، لبههای دو قطعه وکیوم فرمینگ را به یکدیگر جوش میدهد. این جوشکاری، یک اتصال محکم و بادوام ایجاد میکند که باز کردن بستهبندی بدون تخریب آن تقریباً غیرممکن است.

- محدودیت مواد اولیه: برای استفاده از این روش جوش، مواد ترموپلاستیک مورد استفاده برای بستهبندی باید حتماً از

۴. تجهیزات جانبی مهم در فرآیند وکیوم فرمینگ

علاوه بر دستگاههای اصلی شکلدهی، برخی تجهیزات تخصصی دیگر نیز برای تکمیل فرآیند وکیوم فرمینگ ضروری هستند:

۴.۱. دستگاه سیانسی (CNC Machine)

- برای طراحی و ساخت قالبهای وکیوم فرمینگ (اغلب از جنس آلومینیوم) با دقت بالا استفاده میشود.

- دقت بالای دستگاه CNC تضمین میکند که قالب نهایی کاملاً با مشخصات محصول هماهنگ باشد.

۴.۲. دستگاه پرس و قالب دایکات (Die-Cut Press Machine)

- پس از فرآیند شکلدهی، این دستگاه برای برش دقیق و حذف اضافات و لبههای زائد قطعات وکیوم فرمینگ استفاده میشود.

- دایکات همچنین برای برش کارتهای مقوایی به شکل و اندازه نهایی متناسب با قطعه وکیومی به کار میرود.

معایب، چالشها و محدودیتها

با وجود مزایای فراوان وکیوم فرمینگ از نظر سرعت و مقرون به صرفه بودن برای تولید در حجمهای کم تا متوسط، این فرآیند دارای محدودیتهای طراحی، چالشهای تولید و مسائل مربوط به مواد است که رشد آن را در برخی کاربردها محدود کرده است.

۱. محدودیتهای هندسی و طراحی قطعات

وکیوم فرمینگ چالشهای مهمی در رابطه با هندسه نهایی قطعات دارد:

- ضخامت دیواره ناسازگار: قطعات تولید شده ممکن است دارای ضخامت دیوارهای یکنواخت نباشند. این فرآیند تنها برای قطعاتی با دیوارههای نسبتاً نازک و هندسههای ساده مناسب است.

- مشکل در کششهای عمیق: تولید قطعات مقعر با کشش عمیق (نیاز به امتداد یافتن زیاد و عمیقتر در قالب) با استفاده از وکیوم فرمینگ دشوار است. در کششهای عمیق یا گوشههای تیز، دستیابی به توزیع مواد کافی میتواند دشوار باشد.

- جزئیات محدود: دستیابی به جزئیات تیز در سمتی از قطعه که در مقابل قالب قرار دارد، به خصوص در قطعات ضخیم، تا حدودی دشوار است.

- فرمینگ یکطرفه: وکیوم فرمینگ به طور کلی برای قطعاتی ایدهآل است که فقط نیاز به شکلدهی دقیق در یک طرف دارند.

۲. چالشهای فرآیند تولید وکیوم

در طول فرآیند شکلدهی با وکیوم، مدیریت چالشهای فنی زیر برای دستیابی به قطعه با کیفیت ضروری است:

- نشانهها و خطوط قالب (Drag Lines) از قالبهای نر:

- اغلب از بین بردن نشانههای جزئی یا خطوط کشیده شدن قالب از قالبهای نر (مثبت) دشوار است.

- خطوط سردشدگی (Chill Lines):

- این خطوط، که نشاندهنده تغییر سریع در ضخامت مواد هستند ، ممکن است در کنارههای قطعه و در فرآیند شکلدهی دریپ (Drape Forming) ظاهر شوند.

- این مشکل زمانی رخ میدهد که ورقی که ابتدا با سطح قالب تماس پیدا میکند، سرد میشود (چیل میشود) و در نتیجه تمایل کمتری به کشش نسبت به قسمتهای گرم اطراف خود دارد.

- کنترل دمای گرمایش:

- از آنجایی که اکثر پلاستیکها عایقهای خوبی هستند، این خطر وجود دارد که سطح ورق بیش از حد گرم شود، که میتواند قبل از رسیدن کل ورق به دمای شکلدهی، باعث تخریب مواد و تغییر رنگ شود.

- استفاده از حرارت دادن همزمان از دو طرف میتواند این احتمال را به حداقل برساند و زمان کل گرمایش را کاهش دهد.

- نازک شدن ناشی از کشش داخلی (Orientation):

- بیشتر مواد پلاستیکی در طول چرخه گرمایش تمایل دارند که تنش یا جهتگیری داخلی خود را آزاد کنند.

- این حرکت در ورق میتواند باعث نازک شدن آن، قبل از شروع عملیات شکلدهی شود.

- بنابراین، هنگام استفاده از تجهیزات گرمایش تابشی (Radiant heating) معمولی، باید از ورقهایی با جهتگیری بیش از حد اجتناب کرد.

۳. چالشهای مدیریت ضایعات (Trim Scrap)

استفاده از فرآیند وکیوم فرمینگ نیازمند مدیریت دقیق مسائل مربوط به عملیات پس از شکلدهی است:

- ضایعات پیرایش و بازیافت:

- قطعات شکلدهی شده باید پیرایش (Trim) شوند، که منجر به تولید مقداری ضایعات پیرایش میگردد.

- برای پایین نگه داشتن هزینههای مواد، این ضایعات باید به طور مؤثر مورد استفاده قرار گیرند.

- اگر مواد قابل بازفرآوری (Reprocessed) نباشند (غیرقابل بازیافت)، ضایعات باید با ضرر به فروش برسند.

- در برخی موارد، اگر درصد ضایعات بیش از حد شود، میتواند کارایی فرآیند را کاهش دهد.

- (توجه: بسیاری از مواد متداول در وکیوم فرمینگ، مانند PET و HIPS، قابل بازیافت هستند).

- محدودیتهای فنی پیرایش (Trimming):

- لبه پیرایششده در قطعات میتواند قابلیتهای طراحی و عملکردی آن قطعه را محدود کند.

- برای عملیات پیرایش مرسوم، تنها موادی قابل قبول هستند که بدون شکستگی قابلیت پیرایش داشته باشند.

- مواد با کشیدگی کم (Low Elongation) باید با استفاده از تکنیکهای ویژه پیرایش شوند.

نکات فنی و کلیدی برای دستیابی به کیفیت صنعتی و پایدار

دستیابی به کیفیت صنعتی و پایدار در محصولات وکیوم فرمینگ، نیازمند مدیریت دقیق و سیستماتیک جزئیات فنی در تمامی مراحل تولید است.

۱. کنترل دما و سیاست گرمایش

گرمایش ورق کلیدیترین مرحله است. استفاده از هیترهای Zoned برای کنترل جداگانه بخشهای مختلف ورق و تضمین توزیع یکنواخت دما ضروری است. نصب سنسورهای مادون قرمز (IR) برای پایش دقیق دمای سطحی ورق و تنظیم پروفایل دما بر اساس نوع ماده (مثلاً PET: 120-160°C، HIPS: 150-175°C، ABS: 140-180°C) حیاتی است. انجام ماتریس تست گرمایش و کالیبراسیون دورهای هیترها نیز توصیه میشود.

۲. مدیریت خلأ (وکیوم)

نقش پمپ وکیوم، تخلیه سریع و کامل هوای محبوس شده است. معیار مناسب نه صرفاً فشار نهایی، بلکه «سرعت دستیابی به خلأ» و «پایداری آن» است. زمان لازم برای رسیدن به فشار هدف باید کمتر از زمان سفت شدن ورق باشد و فشار خلأ نباید در حین فرآیند افت کند. انجام تست نشت خطوط وکیوم به صورت هفتگی، بررسی و تمیزکاری فیلترهای هوا، و تعویض روغن پمپ ضروری است.

۳. طراحی قالب

زاویه خروج (Draft Angle) (حداقل 3 تا 5 درجه)، سطح صیقلی قالب (برای بستهبندیهای شفاف) یا مات (برای جلوههای خاص)، و طراحی مسیرهای تخلیه هوا (Venting) (سوراخها یا شیارهای ریز) در نقاط عمیق و گوشهها، برای خروج آسان قطعه و جلوگیری از حباب حیاتی است. پرهیز از فرورفتگیهای بسیار عمیق و استفاده از شعاعهای انتقال (انحنا) به جای لبههای تیز در طراحی هندسی قالب به توزیع یکنواخت ضخامت کمک میکند.

۴. توزیع ضخامت و تکنیکهای بهبود آن

حفظ ضخامت یکنواخت در کل قطعه یک چالش مهم است. راهکارها شامل پیشکشیدن ورق (Pre-Stretch) با اعمال فشار هوا یا مکش وکیوم قبل از تماس کامل با قالب برای توزیع ضخامت، گرمایش هدفمند در نقاط خاص با هیترهای zoned، و اصلاح طراحی هندسی قالب (کاهش عمق، تغییر زاویه) است.

۵. عملیات پسفرمینگ (برش و لبهکاری)

پس از شکلدهی و خنکسازی، برش دقیق لبهها و حذف اضافات ورق برای دستیابی به ظاهر نهایی مطلوب حیاتی است. استفاده از قالب برش مکانیکی (دایکات) برای تولید انبوه و برش CNC برای نمونههای دقیق یا هندسههای پیچیده رایج است. فضای کافی برای برش (Trim Allowance) باید در طراحی قالب در نظر گرفته شود.

۶. عیوب رایج و راهحلها

نازکشدن موضعی: علت: دمای بیش از حد، طراحی نامناسب قالب. راهحل: کاهش دما، پیشکشیدن ورق، اصلاح هندسه قالب.

حباب یا عدم تماس کامل: علت: خلأ ناکافی، Venting ضعیف، نشت در خطوط وکیوم. راهحل: افزایش ظرفیت پمپ خلأ، بهبود طراحی Vent، تست نشت منظم.

چینخوردگی: علت: گرمایش نامناسب (بهویژه لبهها)، نگهداری ضعیف لبههای ورق. راهحل: بهبود پروفایل گرمایش، استفاده از گیرههای بهتر، افزایش سرعت فرمینگ.

اعوجاج پس از خنکشدن: علت: خنکسازی ناکافی یا نامنظم، جداسازی زودهنگام. راهحل: افزایش زمان ماندن روی قالب، بهبود سیستم خنککننده.

۷. چکلیست پیش از تولید انبوه

شامل بررسی مجدد گرید و ضخامت ورق، تنظیم و کالیبره کردن هیترها و سنسورها، تست نشت سیستم خلأ، بازبینی طراحی قالب، اجرای تست نمونه و اندازهگیری ضخامت، بهینهسازی پارامترها و بررسی لاگهای تولید.

تاریخچه: از ابداع سلولوئید تا انقلاب دیجیتال

فرآیند وکیوم فرمینگ، به عنوان یکی از روشهای اصلی شکلدهی حرارتی (ترموفرمینگ)، تاریخچهای تکاملی دارد که مستقیماً با موفقیت در شیمی پلیمرهای گرماپذیر گره خورده است.

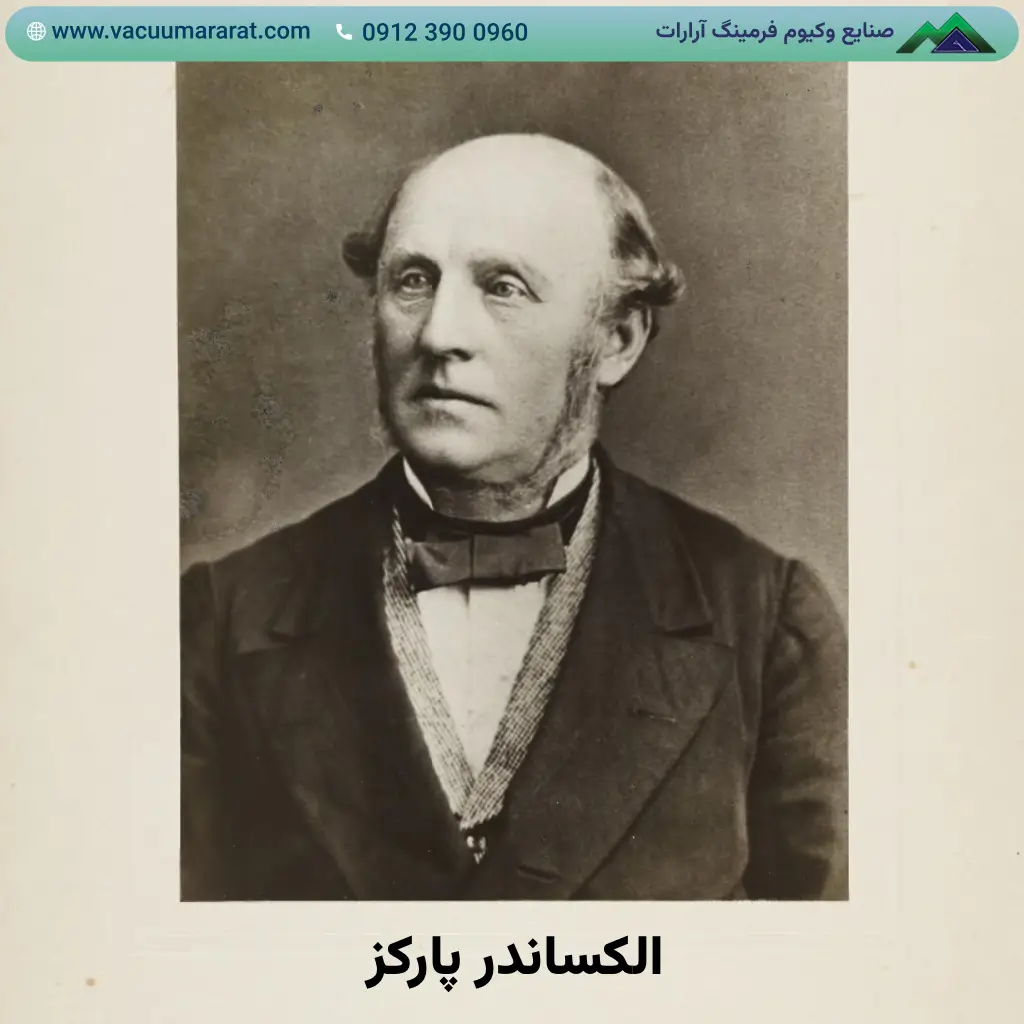

۱. ریشههای اولیه و دوران پیشسازها (۱۸۵۵-۱۸۷۰)

نقطه شروع این فناوری به سال ۱۸۵۵ میلادی در بیرمنگام انگلستان بازمیگردد، جایی که الکساندر پارکز مادهای به نام پارکسین (پیشساز سلولوئید) را اختراع کرد و از بخار برای گرم کردن و شکل دادن به آن استفاده نمود. در دهه ۱۸۷۰، جان وسلی هایت این اختراع را توسعه داد و با استفاده از حرارت بخار و فشار و قالبهای فولادی، ماده سختتری ساخت. این روش به عنوان اولین شکل تجربی ترموفرمینگ در نظر گرفته میشود.

۲. شتاب نظامی و پتنتهای کلیدی (۱۹۳۶-۱۹۴۷)

دوران جنگ جهانی دوم، بهویژه نیاز نظامی به مواد سبک و بادوام مانند ورقهای اکریلیک (پلکسیگلاس) برای ساخت کاکپیت هواپیماها، توسعه وکیوم فرمینگ را شتاب بخشید.

در این دوره پتنتهای بنیادین ثبت شدند که مبنای فرآیندهای مدرن را تشکیل دادند:

- کلاوس ب. اشتراوخ در سال ۱۹۳۸ ماشین ترموفرمینگ با تغذیه رول را اختراع کرد.

- آر. ای. لری (دوپونت) اولین ماشین وکیوم فرمینگ با حرارت رادیانت و نوآوری کنترل ناحیهبندی حرارتی را ثبت کرد.

- اچ. ال. هلوینگ تکنیک «اسنپبک نر» را ثبت کرد که با استفاده از خلأ برای پیشکشیدن ورق داغ، به توزیع یکنواخت ضخامت دیواره در قطعه نهایی کمک میکرد.

- در سال ۱۹۴۷، جی. دبلیو. بورکلند دستگاه وکیوم فرمینگ را ثبت اختراع کرد.

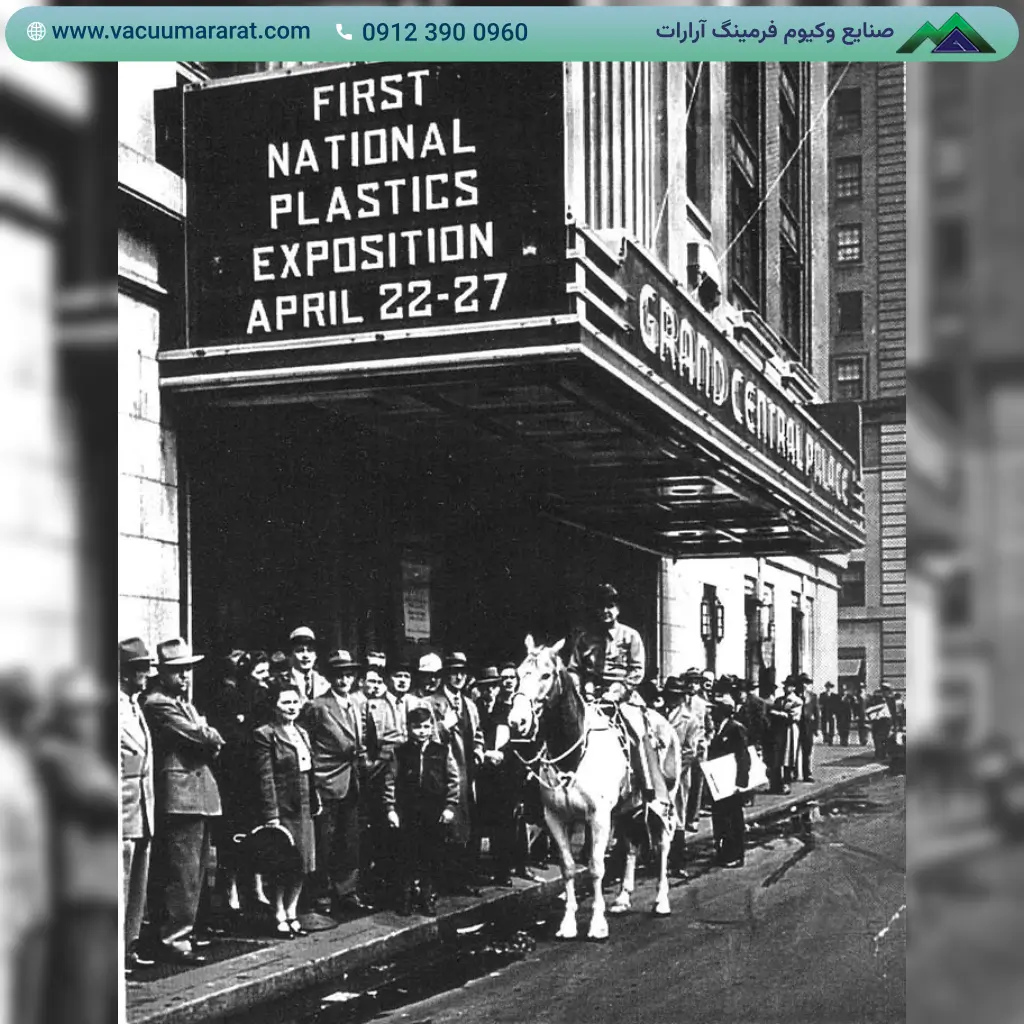

۳. تثبیت صنعتی و تجاریسازی (۱۹۴۷-۱۹۶۰)

پس از جنگ، انتقال دانش فنی نظامی به بخش تجاری سرعت گرفت. نمایشگاه ملی پلاستیک (NPE) در شیکاگو در سال ۱۹۵۰، نقطه عطف ورود رسمی ترموفرمینگ به بازارهای عمومی بود.

در این دوره، اصطلاح «ترموفرمینگ» (شامل شکلدهی خلأ و فشار) تثبیت شد. این فرآیند با تولید سریع بستهبندیهای بلیستر و همچنین قطعات سنگینسنج و بزرگ مانند آسترهای داخلی درهای یخچال (که قالبگیری تزریقی قادر به تولید آنها نبود) جایگاه استراتژیک خود را تثبیت کرد.

۴. عصر اتوماسیون و انقلاب دیجیتال (۱۹۶۰ تا امروز)

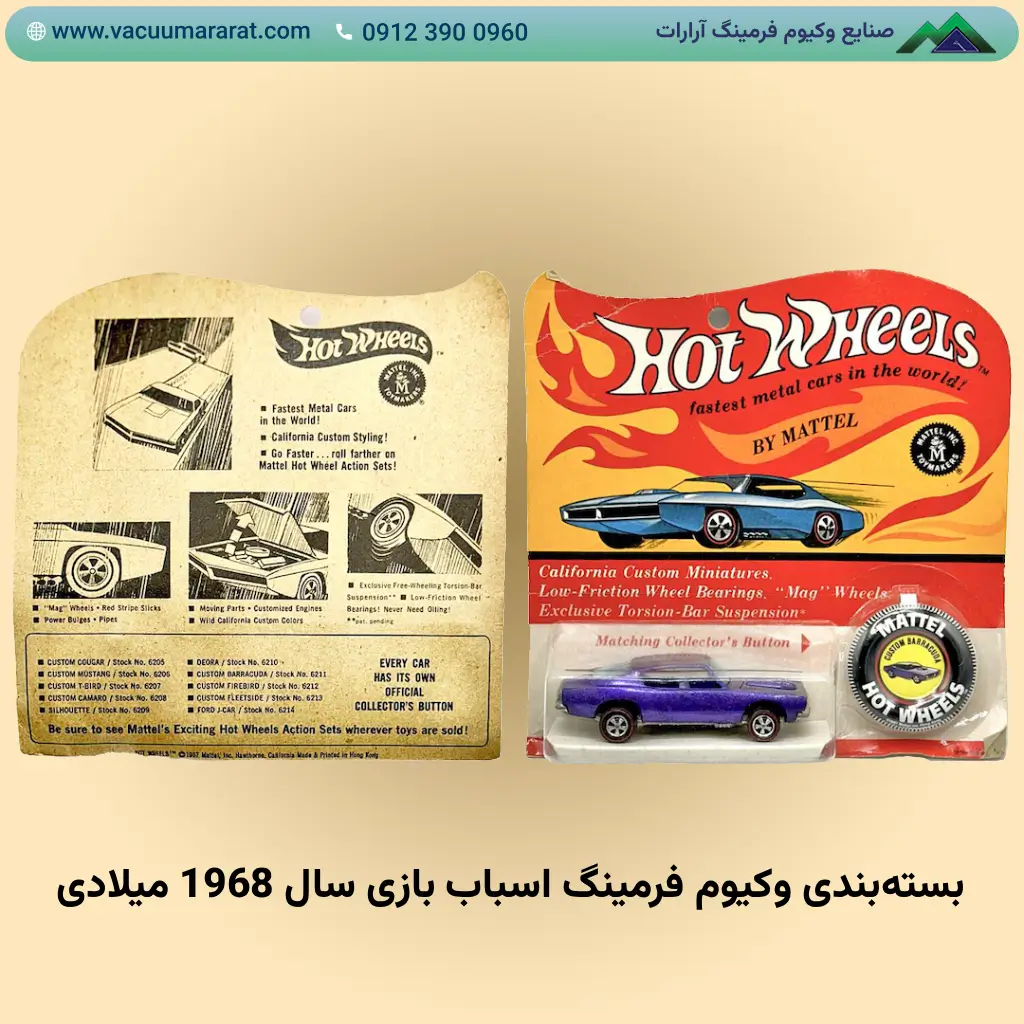

با افزایش تقاضای جامعه مصرفگرا برای بستهبندیهای بصری (مانند صدفی و بلیستر) در دهه ۱۹۶۰، نیاز به دقت ابزارسازی افزایش یافت.

- در دهه ۱۹۷۰، ابزارسازی از روشهای سنتی (مانند ریختهگری ماسه) به سمت ماشینهای فرز کپیبردار و سپس در اواخر دهه ۱۹۸۰ به سمت دستگاههای CNC (کنترل عددی کامپیوتری) و طراحی دو بعدی سوق یافت.

- در اوایل دهه ۱۹۹۰، نرمافزارهای مهندسی به مدلهای سهبعدی (CAD) پیشرفت کردند که امکان برش خودکار و دقیق قالب توسط CNC را فراهم کرد.

امروزه، ادغام CAD/CAM/CNC ساخت ابزار را بسیار کارآمد ساخته و از فناوریهایی مانند قالبهای پرینت سهبعدی برای نمونهسازی سریع استفاده میشود.

جمعبندی و توصیههای اجرایی

برای دستیابی به بستهبندی با کیفیت صنعتی و پایدار در فرآیند وکیوم فرمینگ، نیاز به یک نگاه سیستماتیک به تمام اجزای فرآیند است. موفقیت در تولید انبوه کلید در ترکیب سه عامل کلیدی است: انتخاب ماده مناسب، طراحی دقیق قالب، و کنترل دقیق پارامترهای فرآیند (دما، خلأ، زمانبندی). هر جزئیات کوچکی، از انتخاب اولیه ورق تا عملیات پسفرمینگ، میتواند اثر بزرگی بر نتیجه نهایی بگذارد.

توصیههای اجرایی

- کنترل کیفیت و تست سیستماتیک: اجرای دقیق نکات فنی و پایش مداوم کیفیت در هر مرحله، خطر بروز خطا در تولید انبوه را بهطور قابل توجهی کاهش میدهد. استفاده از نمونهسازی سازمانیافته با ماتریسهای تست و برنامه کنترل کیفیت منظم، به ایجاد یک فرآیند پایدار و تکرارپذیر منجر میشود.

- بهرهگیری از فناوریهای سریع نمونهسازی: در پروژههای جدید و مراحل اولیه طراحی، استفاده از قالبهای نمونه ساخته شده با تکنولوژی پرینت سهبعدی میتواند زمان و هزینههای توسعه را چشمگیری کاهش دهد.

- توجه به جزئیات فنی: کنترل دقیق دمای گرمایش، مدیریت بهینه خلأ (سرعت دستیابی به خلأ و پایداری آن)، و طراحی مهندسی شده قالب (شامل زوایای خروج مناسب و مسیرهای تخلیه هوا) برای تضمین توزیع یکنواخت ضخامت، حیاتی هستند.

- انتخاب شریک متخصص: صنایع بستهبندی وکیوم فرمینگ آرارات، با تکیه بر تجربه چندین ساله و دانش فنی، خدمات مشاوره و تولید بستهبندیهای وکیوم فرمینگ سفارشی را ارائه میدهد. اتخاذ یک رویکرد پیشگیرانه تضمین میکند که هر بستهبندی تولید شده، نه تنها انتظارات عملکردی را برآورده کند، بلکه از نظر ظاهری نیز بینقص و از نظر تولید، مقرون به صرفه و پایدار باشد. برای دریافت مشاوره تخصصی و سفارش تولید، توصیه میشود با کارشناسان مجرب آرارات تماس گرفته شود.

پرسشهای متداول (FAQ) درباره وکیوم فرمینگ

۱. وکیوم فرمینگ چیست؟

وکیوم فرمینگ یک روش پیشرفته در شکلدهی حرارتی است که طی آن ورقهای ترموپلاستیک با استفاده از گرما نرم شده و سپس با مکش خلأ بر روی قالب کشیده میشوند تا شکل قالب را بگیرند.

۲. چرا بستهبندی وکیوم فرمینگ تا این حد اهمیت دارد؟

این تکنیک مفهوم حفاظت از محصول را به سطحی نوین ارتقا بخشیده و بستهبندیهایی خلق میکند که نه تنها ایمنی محصول را تضمین میکنند، بلکه جلوهای زیبا و دلنشین به آن میبخشند.

۳. مزایای اصلی استفاده از وکیوم فرمینگ در بستهبندی کدامند؟

مزایای اصلی شامل محافظت جامع و امنیت بالا، مقرونبهصرفه بودن، جذابیت بصری و شفافیت، انعطافپذیری و قابلیت سفارشیسازی، پایداری زیستمحیطی و سرعت بالای تولید است.

۴. چه نوع محصولاتی را میتوان با وکیوم فرمینگ بستهبندی کرد؟

تقریباً طیف وسیعی از محصولات از جمله کالاهای مصرفی (آرایشی و بهداشتی، الکترونیکی، اسباببازی)، مواد غذایی (شیرینی، گوشت، لبنیات)، اقلام پزشکی و دارویی، و حتی قطعات صنعتی را میتوان با این روش بستهبندی کرد.

۵. متداولترین مواد اولیه مورد استفاده در وکیوم فرمینگ چیست؟

مواد اولیه اصلی شامل PET (پلیاتیلن ترفتالات)، PVC (پلیوینیل کلراید)، HIPS (پلیاستایرن مقاوم به ضربه) و ABS (آکریلونیتریل بوتادین استایرن) هستند.

۶. آیا بستهبندیهای وکیوم فرمینگ از نظر اقتصادی مقرونبهصرفه هستند؟

بله، وکیوم فرمینگ یکی از روشهای اقتصادی و کمهزینه برای تولید بستهبندی است که به دلیل هزینه پایین قالبسازی و کاهش هزینههای لجستیک، منابع را بهینه میکند.

۷. چه مدلهای رایجی از بستهبندی وکیوم فرمینگ وجود دارد؟

انواع رایج شامل بلیستر پرسی، بلیستر میانکارتی، کشویی، هایفرکانس، صدفی (ظرفی و کارتی)، ظروف دربدار، ظروف قابل سیل و اسکین پک میباشند.

۸. چگونه از کیفیت و دوام بستهبندی وکیوم فرمینگ اطمینان حاصل میشود؟

از طریق کنترل دقیق دما و سیاست گرمایش ورق، مدیریت بهینه خلأ، طراحی مهندسیشده قالب، توزیع یکنواخت ضخامت و اجرای برنامه جامع کنترل کیفیت در تمام مراحل تولید.

۹. آیا مواد وکیوم فرمینگ قابلیت بازیافت دارند؟

بسیاری از مواد اولیه پرکاربرد مانند PET و HIPS قابل بازیافت هستند که به کاهش ردپای زیستمحیطی کمک میکند.

۱۰. وکیوم فرمینگ علاوه بر بستهبندی، در چه صنایع دیگری کاربرد دارد؟

علاوه بر بستهبندی، در تولید قطعات پلاستیکی برای صنایع خودروسازی، هواپیماسازی، بدنه دستگاهها و تجهیزات، قایقسازی، لوازم خانگی و قطعات محافظ نیز کاربرد دارد.

آخرین مقالات

این پست چقدر برایتان مفید بود؟

روی یک ستاره کلیک کنید تا امتیاز دهید!

میانگین امتیاز 5 / 5. تعداد امتیاز: 34

امتیازی ثبت نشده! اولین نفری باشید که به این پست امتیاز میدهید.

شما اینجا هستید: خانه